Cold or Hot Peel A3 DTF Transfer Film

At Lorin Transfer, we understand that choosing the right a3 dtf transfer film is critical to your business success. Whether you are running a small POD studio, a garment factory, or a global apparel brand, the key purchasing priorities are always the same: reliable transfer performance, superior wash durability, and a premium final product experience. Our a3 dtf transfer film is engineered to meet and exceed these demands, making your printing process easier and your products stand out in the market

Specifications

Product Name DTF Film

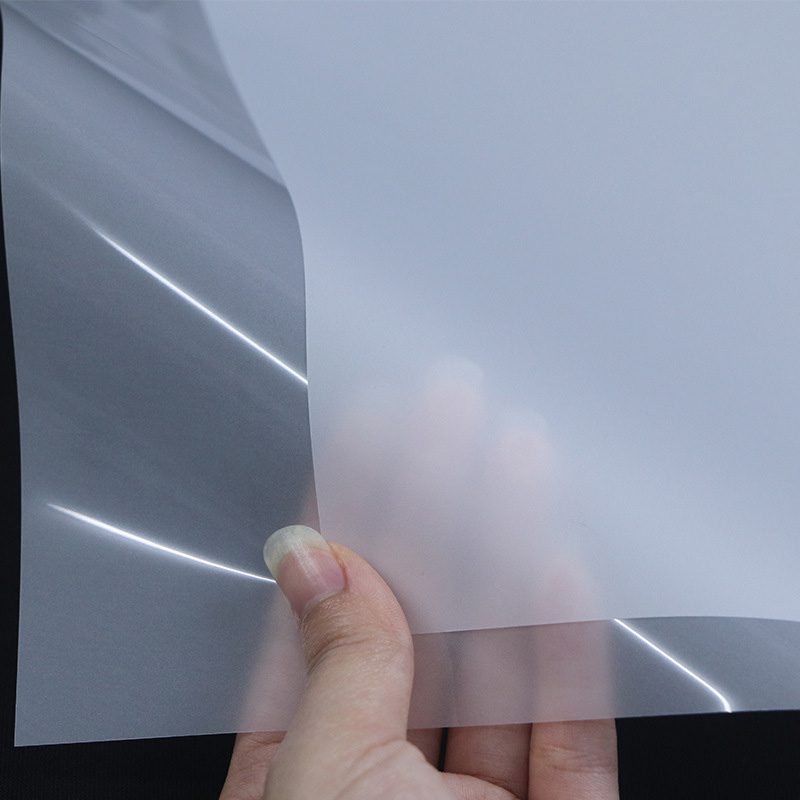

Material Polyester

Size A3/A4/Roll

Thickness 75 micron

Peel Method Cold/Hot Peel

Transfer Temperature 130-150℃

Transfer Time 10-15s

Features

- Uniform & Clean Powder

Our DTF heat transfer film’s coating technology, continuously upgraded through R&D, achieves uniform powder adhesion and thoroughly clean powder shaking, effectively reducing powder residue. It fundamentally solves common industry issues like oil bleeding, uneven powder adhesion, and easy peeling after transfer, ensuring stable and reliable direct-to-film transfer results. - Reliable Peel Consistency (Instant Peel, Hot Peel & Cold Peel Options)

Every print matters. Our films ensure clean, consistent transfer without leftover adhesive or ghosting. Whether you choose Hot Peel for faster production or Cold Peel for softer finishes, you can achieve a 100% successful transfer rate, minimizing waste and reducing production costs. - High Color Fidelity

With special coating and precise color technology, it highly restores color details, saturation, and layering of original designs—ideal for custom DTF printing and DTF transfers, custom needs—ensuring vivid, lifelike colors on transferred products. - High Efficiency

Our a3 dtf transfer film eliminates the need for extra weeding or laminating processes, directly simplifying DTF transfers heat press workflows, shortening working hours, and effectively boosting overall efficiency. Meanwhile, it breaks limitations on pattern complexity and fabric types, creating more possibilities for flexible manufacturing. - Mainstream Printer Compatibility

It’s compatible with mainstream inkjet printers and other models for dtf transfer sheets applications, avoiding extra costs and operational troubles from device incompatibility. This allows customers to easily connect with existing production equipment, lowering the entry barrier. - Anti-Static Coating

An advanced anti-static layer prevents powder scattering outside the print zone, reducing defects and ensuring stable, uninterrupted printer operation. This is especially important for small studios or businesses using desktop DTF printers.

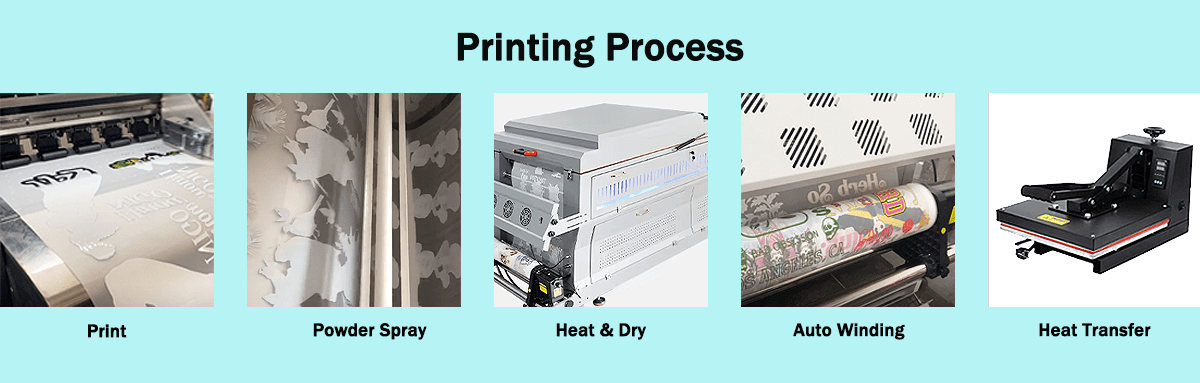

How to Use?

Using our a3 dtf transfer film is simple (ideal for both beginners and pros):

1. Printing: Load the film into an inkjet printer (compatible with Epson, Roland, etc.). Print your design inmirror image (critical for correct orientation after transfer).

2. Powder Coating: Immediately after printing, spread hot melted powder evenly over the inked area. For fine details (e.g., small text), use a fine brush to ensure full coverage.

3. Curing: Cure the powder with an oven or heat press: 150’c for 2-3 minutes (until powder melts into a smooth layer).

4. Heat Transfer: Place the cured a3 dtf transfer film on the substrate (e.g., a T-shirt). Use a heat press: 130-150°C, 10-15seconds, medium pressure.

5. Peeling: Let the film cool slightly, then peel (cold/warm peel both work-our film’s stability makes peelingeasy without damaging the design).

Pro Tip: For dark fabrics, pre-press for 3 seconds to remove moisture/wrinkles; for delicate fabrics (silk), use the lower end of the temperature range (130°C) and lighten pressure.