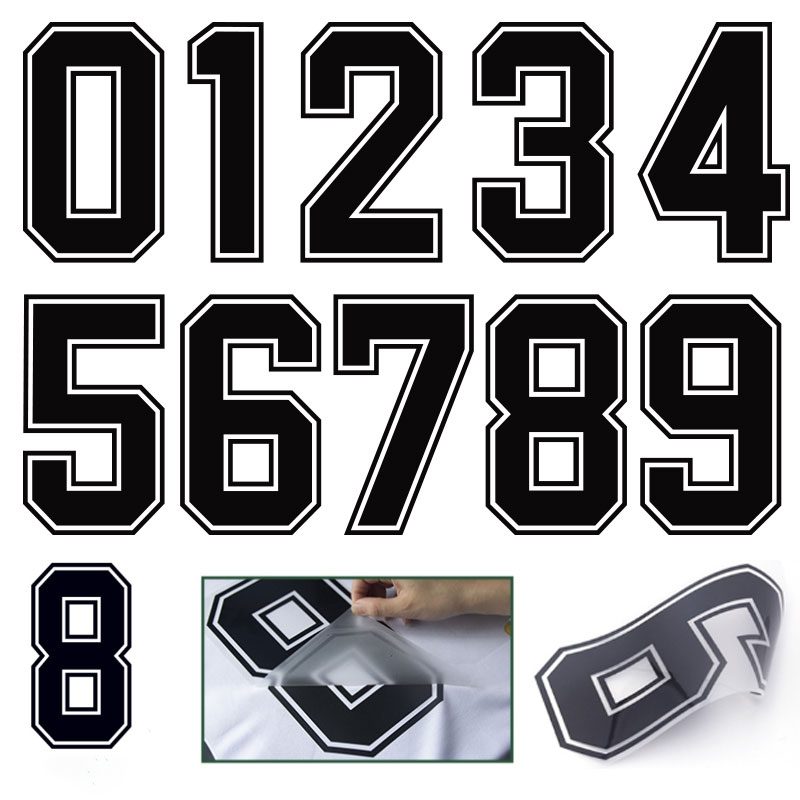

Heat Transfer Numbers For Jerseys

Create customized, professional-grade sportswear and apparel designs with our Premium Heat Transfer Numbers for Jerseys. Engineered for high elasticity and exceptional durability, these heat press numbers are made from anti-sublimation, soft-touch materials that retain their shape and vibrant color even after repeated machine washes.

Specifications

| Product Name | Heat Transfer Numbers (Flat Transfers) |

|---|---|

| Material | High-Quality, Anti-Sublimation Material |

| Finish | Soft Touch, Skin-Friendly, Matte |

| Color | Customizable |

| Temperature Range | 130°C–150°C |

| Transfer Time | 10–15 seconds |

| Peeling Method | Hot Peel / Cool Peel |

| Elasticity | High Elastic, Flexible |

| Durability | Washable, Long-lasting Color Retention |

| Suitable Fabrics | Cotton, Polyester, Spandex, Knitted, Elastic Fabrics, Activewear |

| Application | Jerseys, Sportswear, T-Shirts, Team Uniforms, Bags |

| MOQ | Customizable based on order size |

Key Features

- High-Elastic, Soft-Touch Finish

Ensures excellent flexibility and a skin-friendly, comfortable feel on garments. - Exceptional Durability & Washability

Maintains shape and vibrant color after multiple machine washes without cracking, fading, or peeling. - Strong Adhesion & Clean Transfer

Powerful adhesive ensures long-lasting bond to fabric, ideal for high-mobility sportswear. - Customizable Colors & Sizes

Fully customizable to match your brand, team, or event design specifications. - Hot and Cold Peel Options

Flexible workflow with immediate hot peel or delayed cold peel after cooling. - Eco-Friendly, Anti-Sublimation Material

Prevents ink migration and color bleeding for crisp, vivid transfer results.

Kickstart Your Custom Heat Transfer Numbers Order: Here’s What We Need to Know

To make sure we craft the ideal heat transfers that fit your exact needs, please share the following details when you reach out to us:

- Artwork Files: Do you already have a final print-ready file prepared (e.g., in AI format)?

- Transfer Effect/Material: What type of heat transfer are you targeting? (For example: Offset transfers, Anti-sublimation transfers?)

- Garment Fabric Type: What kind of fabric will the heat transfer be applied to? (e.g., 100% cotton, polyester, or blended fabrics)

- Estimated Order Quantity: What’s your approximate order volume? (This helps us identify the most budget-friendly production method for you)

Step-by-Step Guide to Heat Transfer Numbers Application & Post-Processing

To ensure your heat transfer numbers for jerseys achieve consistent, long-lasting results, follow this detailed operational workflow — plus key recommendations for post-care:

- Pre-Press Prep & Pre-Heating Stage

Goal: Eliminate surface moisture and wrinkles from the garment to create a smooth, even base for transfer placement. This step is critical to ensuring strong adhesion between the transfer and fabric, and preventing defects like bubbling or peeling. Key Settings:

Temperature range: 130–150 °C

Duration: Around 5 seconds

Pressure: Medium intensity - Heat Press Operation Steps

Operating Process: Place the heat transfer numbers on jerseys with the design side facing upward. Lower the heat press platen, and confirm that pressure is evenly distributed across the entire design area (uneven pressure can lead to partial transfer failure). Critical Parameters:

Temperature range: 130–150 °C

Duration: 10–15 seconds

Pressure: ≥ 0.24 kgf/cm² (calibration with a pressure gauge is strongly advised for accuracy) - Carrier Sheet Peeling Techniques

Different peeling methods suit varied transfer materials — choose based on your specific product:

Hot Peel: Remove the carrier sheet immediately after lifting the heat press platen, while the transfer is still hot (do not let it cool down first).

Warm Peel: Allow the heat transfer numbers to cool for 5–10 seconds until it feels warm (but not hot) to the touch, then peel off the carrier sheet.

Cold Peel: Wait for heat transfer numbers to cool fully to room temperature (approximately 1 minute) before peeling away the carrier sheet. - Post-Curing Requirements & First Wash Guidelines

Required Post-Curing Time

After the heat press step, lay the garment flat and let it rest for a minimum of 48 hours (or adhere to the specific recommendations from your ink/adhesive supplier). This period allows inks and adhesives to fully cure, which is essential for maximizing wash resistance and long-term durability of the design.

First Wash Best Practices

Once the 48-hour curing period is complete, turn the garment inside out and wash it on a gentle cycle with cold water. This method preserves the integrity of the transfer design and prevents premature fading or peeling.

Elevate your apparel with a professional, long-wearing finish using our customizable heat transfer numbers — inquire about a sample or request a quote now!